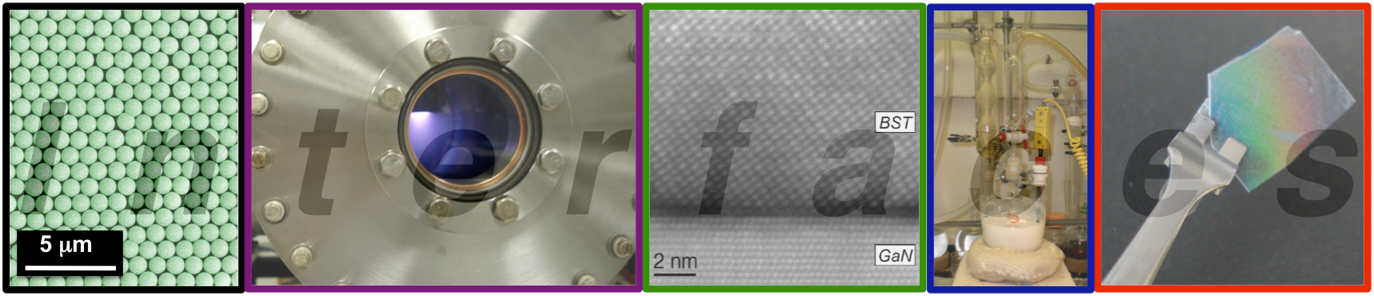

Interfacing materials. Interfacing disciplines.

Home | PI Info | Research | Publications | Mentoring/Outreach | Links

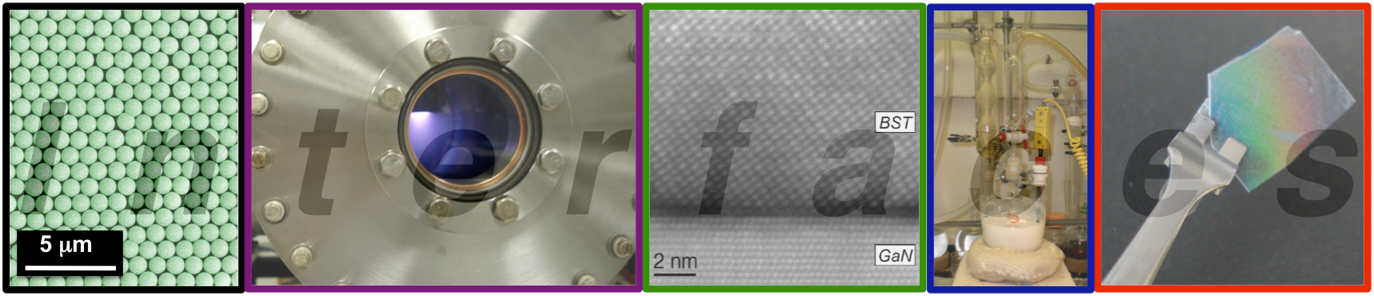

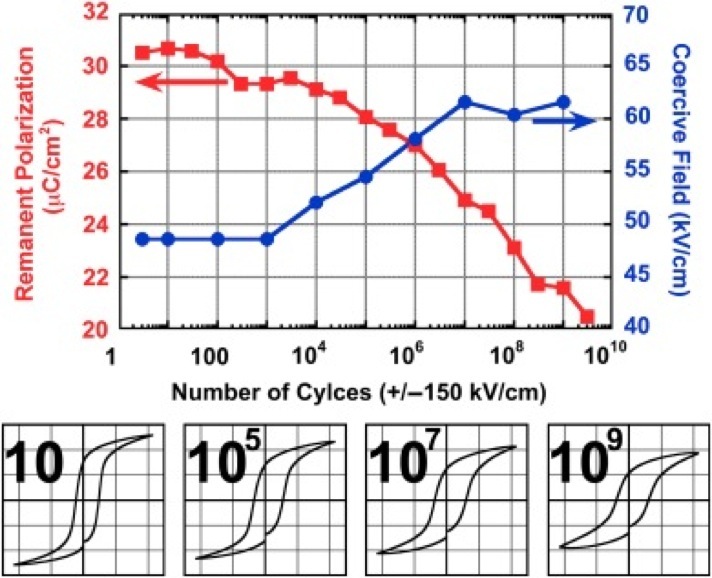

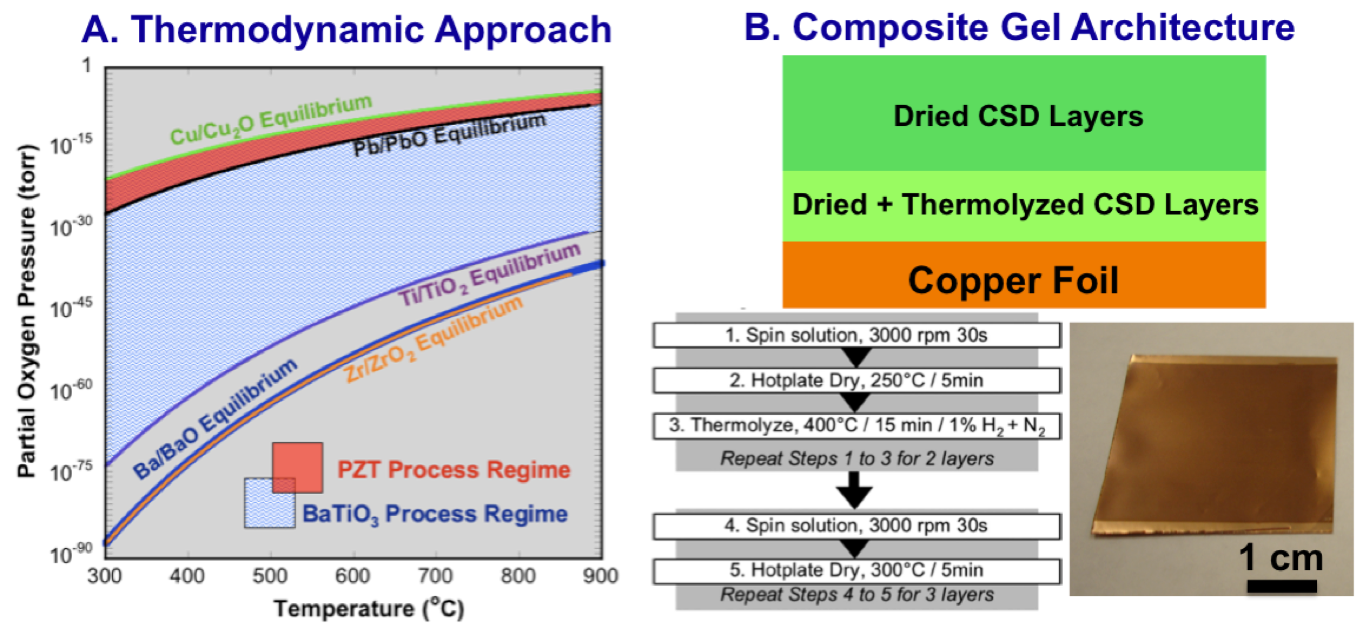

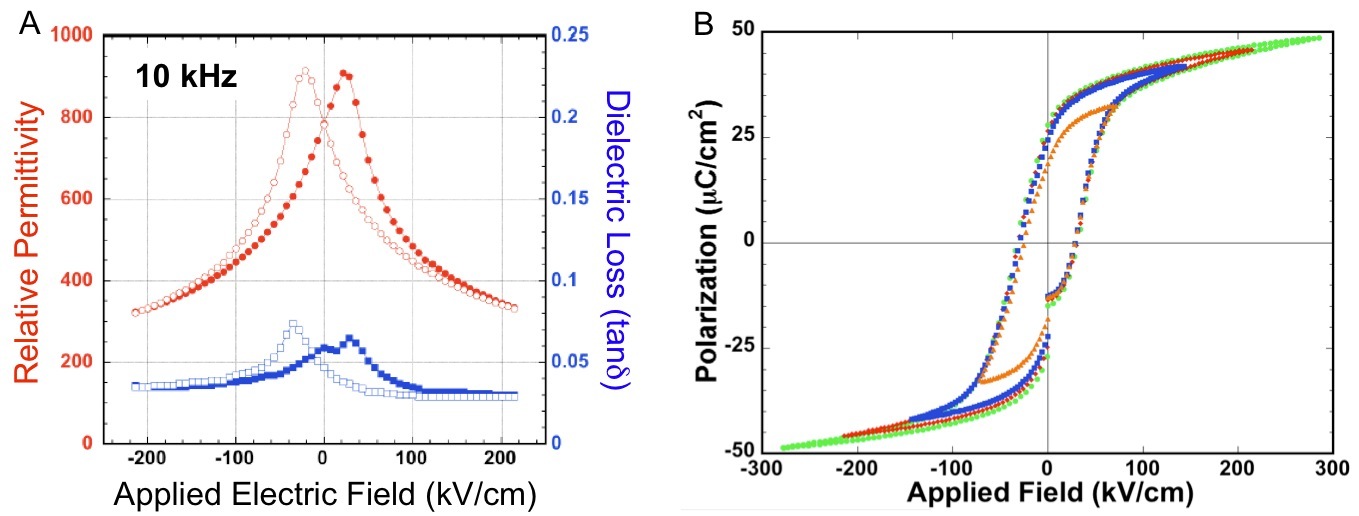

Despite more than two decades of research, ferroelectric oxide thin films have yet to find widespread commercial use. A limiting factor is the need for expensive noble metal or conductive oxide electrodes that permit the necessary high temperature crystallization / sintering of the ferroelectric oxide. Research during the last decade has developed equilibrium processing (Fig. 1A) for ferroelectric BaTiO3 on base metals (Cu, Ni, see Ref. 3). However, lead zirconate titanate (PZT) ferroelectric films, which show higher ferroelectric polarizations and greater piezoelectric response, are difficult to process in thermodynamic equilibrium with copper because of the narrow equilibrium window, high vapor pressure for Pb, and low crystallization temperature for PZT. Therefore, a process strategy that kinetically avoids oxidation of the copper substrate is necessary. A critical balance in the thermal budget must be struck to provide sufficient thermal energy to drive gel consolidation and avoid cracking while limiting the time at temperature to avoid copper oxidation. The composite gel architecture, which uses chemical solution deposition (CSD) of the PZT thin films (Fig 1B, see Ref. 2) is found to meet these needs. Initial layers of the gel are thermolyzed and act to protect the copper from oxidation while subsequent layers are dried at higher temperatures to improve gel consolidation and prevent cracking upon gel-to-ceramic conversion. Upon final anneal in a reducing nitrogen atmosphere, ferroelectric PZT thin films with ferroelectric and dielectric properties comparable to device quality PZT films on noble metal electrodes can be realized (Fig. 2). In fact, when Cu2O is fully avoided at the interface, these PZT films show ferroelectric fatiguing behavior similar to PZT on platinized silicon (Fig 3, see Ref. 1.). These films can undergo more than a billion switching cycles and can recover more than 85% of their fatigued polarization upon annealing above the Curie temperature (Fig 3B).

Fig. 1: Thermodynamic vs. kinetic approaches to integrating ferroelectric oxide films on base metals. (A) Phase diagram showing lines of thermodynamic equilibrium between elemental metals and their simple oxides. Oxides are stable above these lines and metals are stable below these lines. The equilibrium process window of temperature and oxygen partial pressure for BaTiO3/Cu (blue region) is shown to be much larger than for PZT/Cu (red region). (B) Kinetic avoidance is preferred for integration of PZT on Cu. I have developed a “Composite Gel Architecture” that eliminates oxidizing organics at the PZT/copper interface and adequately consolidates the gel structure to avoid cracking upon ceramic conversion.

Integrating Ferroelectric Oxides with Base Metals

Related Publications

1. M. D. Losego and J-P. Maria, “Reproducibility and ferroelectric fatigue of lead zirconate titanate (PZT) thin films deposited directly on copper via a composite gel architecture.” J. Amer. Ceram. Soc. 93 3983 (2010). DOI

2. M. Losego, J. Ihlefeld, J-P. Maria, “The importance of solution chemistry in preparing sol-gel PZT thin films directly on copper surfaces.” Chem. Mat. 20 303 (2008). DOI

3. J. Ihlefeld, M. Losego, R. Collazo, W. Borland, J-P. Maria, “Defect chemistry of nano-grained barium titanate films.” J. Mater. Sci. 43 38 (2008). DOI

4. M. Losego, L. Jimison, J. Ihlefeld, J-P. Maria, “Ferroelectric response from lead zirconate titanate thin films prepared directly on low-resistivity copper substrates.” Appl. Phys. Let. 86 172906 (2005). DOI

Fig. 3: Ferroelectric cycling and fatigue measured for PZT thin films prepared on copper substrates. (A) Remanent polarization and coercive field measured at increasing switching cycles. Polarization hysteresis loops below the plot show fatiguing of the PZT film at several decades. (B) Polarization hysteresis loops showing ferroelectric response before cycling, after 3 billion cycles, and after annealing fatigued film above the Curie temperature.

Fig. 2: Performance of PZT thin films on copper using the composite gel architecture. (A) Tuning of dielectric constant with applied field at 10 kHz, room temperature. (B) Embedded ferroelectric polarization switching loops exhibiting performance comparable to PZT on standard noble metal electrodes.

A

B